The blast furnace skip hoist is protected against overspeed on the motor side by a mechanical overspeed switch with integrated speed increasing gear. The universal encoder system U-ONE® is to replace the outdated sensor systems on both the motor and drum sides. Thanks to its modular design it is possible to adapt the system to meet all of the customer requirements. Direct attachment of the basic unit eliminates mechanical inaccuracies resulting from gearbox backlash and supports improved control response.

Blast furnace/Skip hoists : Retrofitting a U-ONE provides higher accuracy and improves availability

Pilger mill in tube rolling mills - hot and cold pipe detection

Higher production quality and throughput

- Universal encoder system U-ONE replaces inaccurate mechanical components

- Directly attachable compact basic U-ONE unit

- EMC safe signal transmission via fiber optic cable

- Electronic function modules protected in switchboard

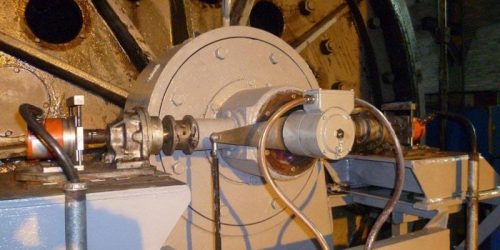

Before: The sensors mounted at an intermediate gear can‘t reach the

necessary accuracy for precise positioning.

Task

- The blast furnace skip hoist is protected against overspeed on the motor side by a mechanical overspeed switch with integrated speed increasing gear.

- On the drum side two absolute encoders mounted on a distribution gearbox supply position signals. As part of a modernization project outdated sensors need to be replaced with up-to-date systems.

- Objectives include simplification of mechanical attachments, elimination of inaccuracies as well as all-round better control response. In addition, susceptibility to EM disturbances is to be reduced and, as a consequence, increase the robustness and availability of the installation.

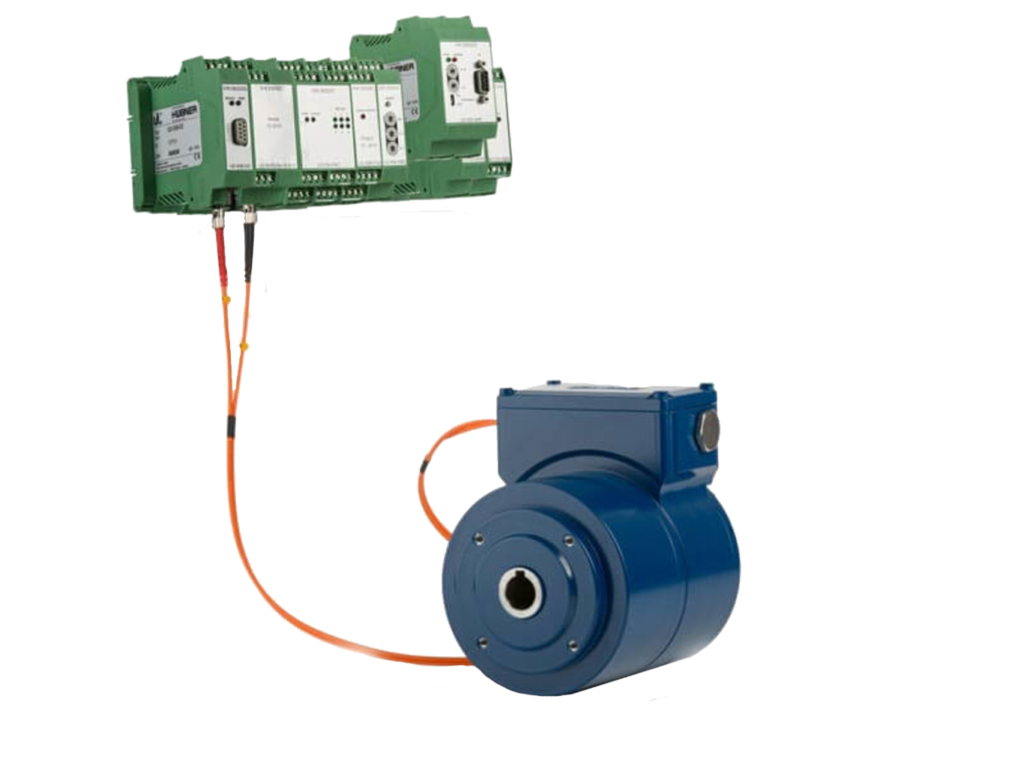

After: The direct mounted basic unit of the universal encoder system U-ONE® provides precise signals to the electronic modules in the control cabinet.

The Hübner Giessen solution

- The universal encoder system U-ONE® is to replace the outdated sensor systems on both the motor and drum sides.

- Thanks to its modular design it is possible to adapt the system to meet all of the customer requirements. Direct attachment of the basic unit eliminates mechanical inaccuracies resulting from gearbox backlash and supports improved control response.

- Signal transmission via fiber optic cable eliminates the effects of EMC issues. The EGS module facilitates easy programming of the switching points for overspeed monitoring purposes.

- The AMS module with SSI interface provides values for position sensing. In addition, the ERC module allows users to conveniently program position switching points without modifying the programming of the PLC.

Products and Accessories

Case Study Number

- TP3

Challenge

- The increasing flexibility of production lines requires a high adaptability of sensors. Continually changing object geometries, different temperatures and very high radiation or surrounding temperatures are no rarity.

- In a pilger mill those rough conditions can be found, among others in the production of seemless steel pipes. The raw steel blocks, each weighing a few tons are heated up first in a round oven at a temperature of 1300 °C.

- After descaling of the surface, the steel block is prepunched in a hole press with a strength from a converted 2000 t. In the next sloping rolling mill the growing pipe rotates between two rollers that are positioned at an angle to each other. The punching is widened to the size of the mandrel diameter.

Previous solution / Competitor product

- N/A

Solution

- The sensor that was installed at this application is the HMD OKA 2038.38 G with tube OL 19.

- The signal of the infrared sensors controls the movement of centering device and abutment. The point of view is restricted by the tube and prevents disturbances by steam in the cooling phase.

- An optimum adaptation to the operating conditions is given due to the adjustable response temperature. The HMD with self-learning response temperature (Auto-Teach function) is suited to continually changing conditions.

- The compact sensor with a stainless steel housing can withstand surrounding temperatures of up to 75° C. The use of a cooling jacket raises this up to 200° C.

- Alternatively sensors with fibre optic cables are available which permit an application at ambient temperatures up to 600° C without cooling.

Customer Benefits

- Maintenance-free

- High temperature stability

- Recognition of hot objects at big distances

- Self adjustment with Auto-Teach or step switch for the response temperature

Product Part number

- OKA 2038.38 G

Brand

- Proxitron

Accessories

- Piros swivel stand HM2

- Tube OL 19

- Pilot light unit (for alignment) DAK 308 + OL 26

- Different cable lengths (e.g. 15 m)

Customer Testimonial

compared to previous solution or competition

Case Studies

Other Solutions in Hot Rolling Mills

Sample case study title lorem ipsum here

Short description of the problem solved, maybe include the client name.

Sample case study title lorem ipsum here

Short description of the problem solved, maybe include the client name.

Sample case study title lorem ipsum here

Short description of the problem solved, maybe include the client name.