Home Case Studies

Filter

-

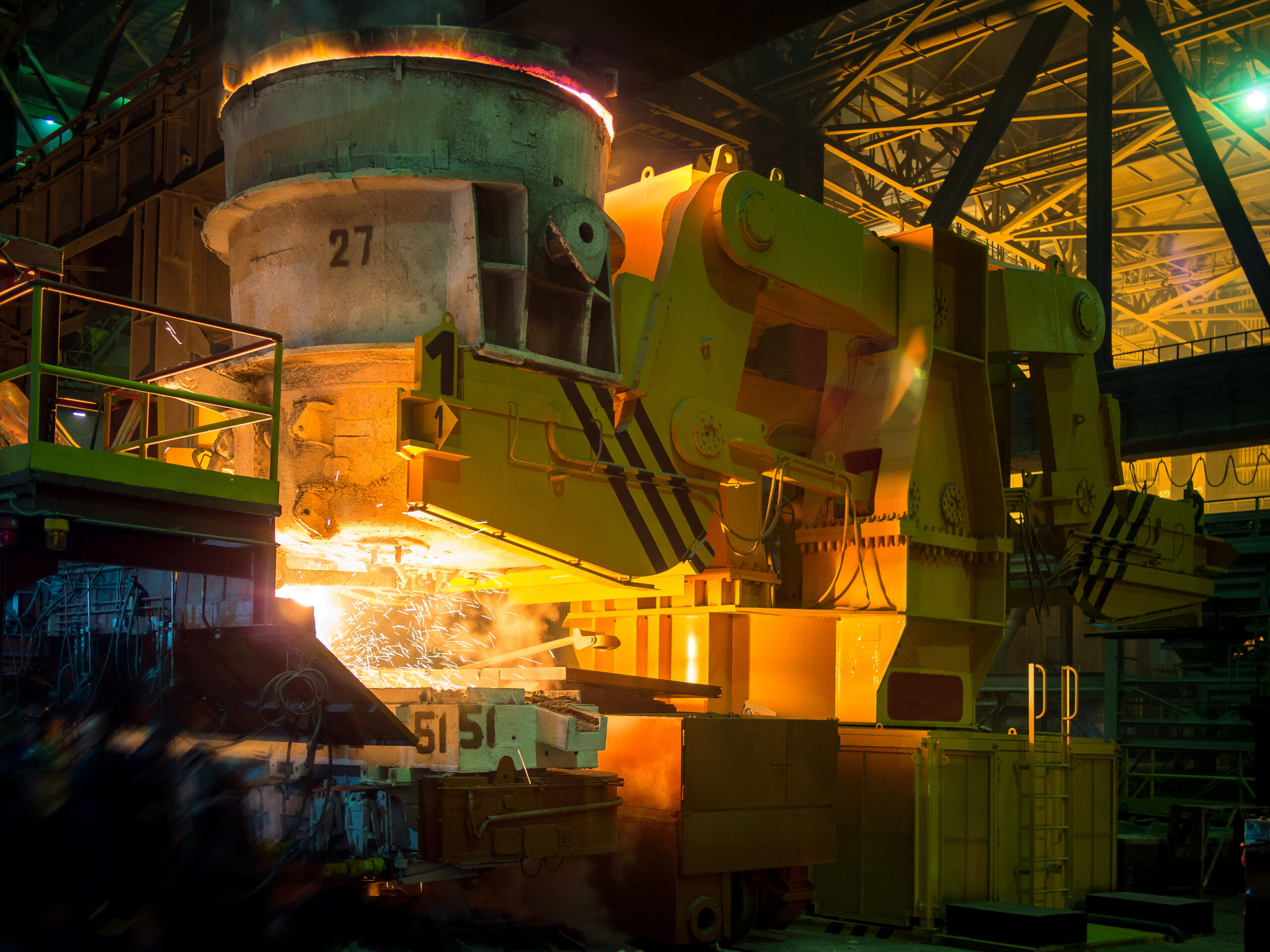

Online condition based monitoring of Tundish

IR camera continuously monitors the ROI of tundish, generating an alarm if temperature exceeded 300⁰ thereby improving ladle lifetime with early detection and selective repairs. Home Case Studies Online condition based monitoring of Tundish Online condition based monitoring of Tundish Home Case Studies Pilger mill in tube rolling mills... -

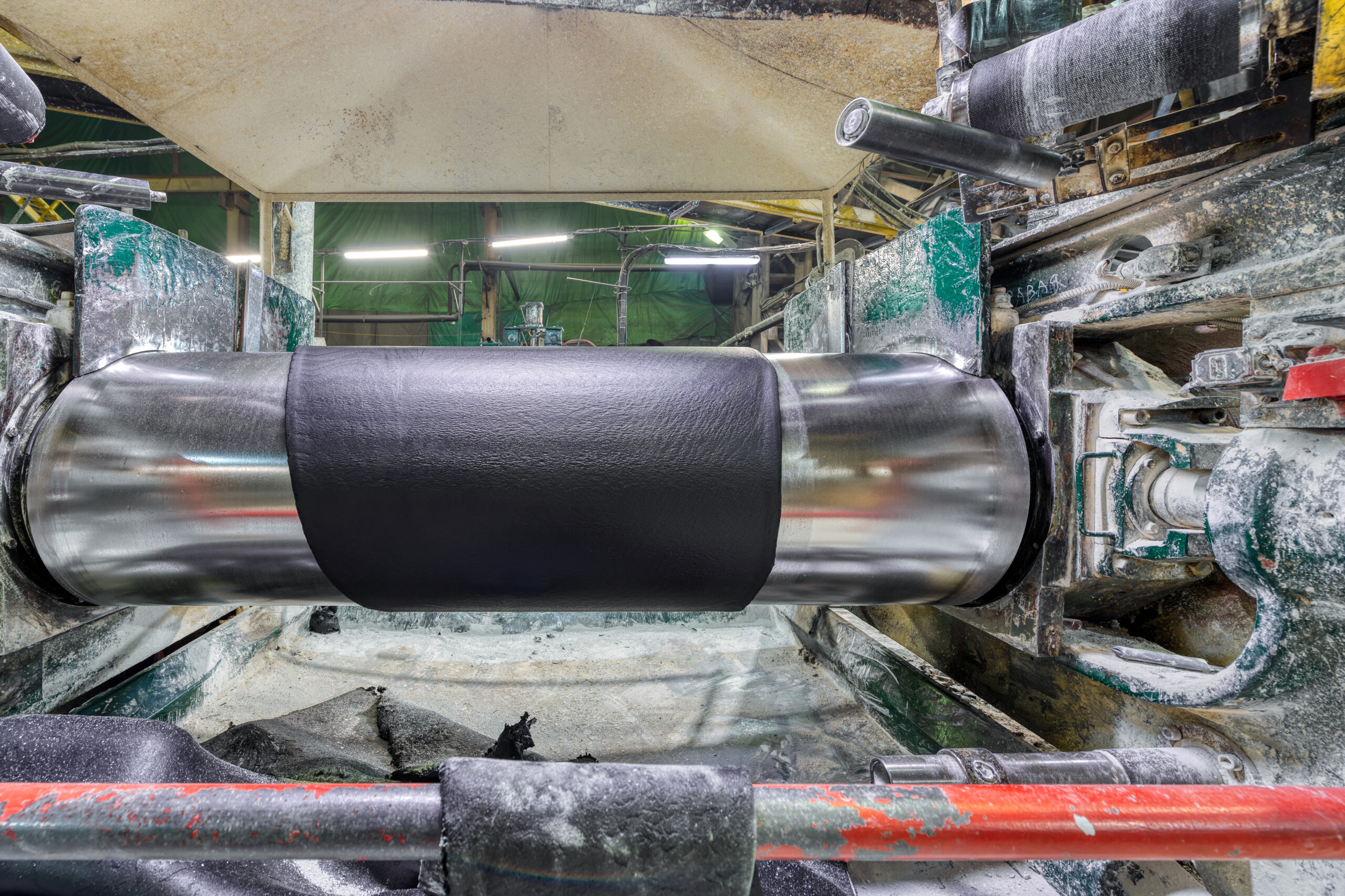

Roll Change Detection: High temperature proximity for wet areas with heat radiation proximity fo

Short circuit protected proximity switch for 10 – 55 V DC with 3-wire technology was used for the accurate detection of roll change in very harsh operating conditions. The high temperature electronics can withstand ambient temperature of up to 100⁰CHome Case Studies Roll change detection on work roll backup roll... -

Pinch roll rod detection before laying head

Hot Metal Detector was used for the detection of long product rolling. The sensor’s small spot size is big enough to capture bar fluttering but without sensing crop ends. No water cooling was required as the sensor was provided with a fibre optic cable between the optics and the electronics.... -

Measuring temperature inside metal in Reheating Furnace

The short wavelength high performance pyrometer with wall mounting monitors temperature of metal inside the reheating furnace and ensures slabs are optimally heated. Direct temperature measurement of metal is made possible with option to have a video view of the inside of the furnace.Home Case Studies Measuring temperature inside metal... -

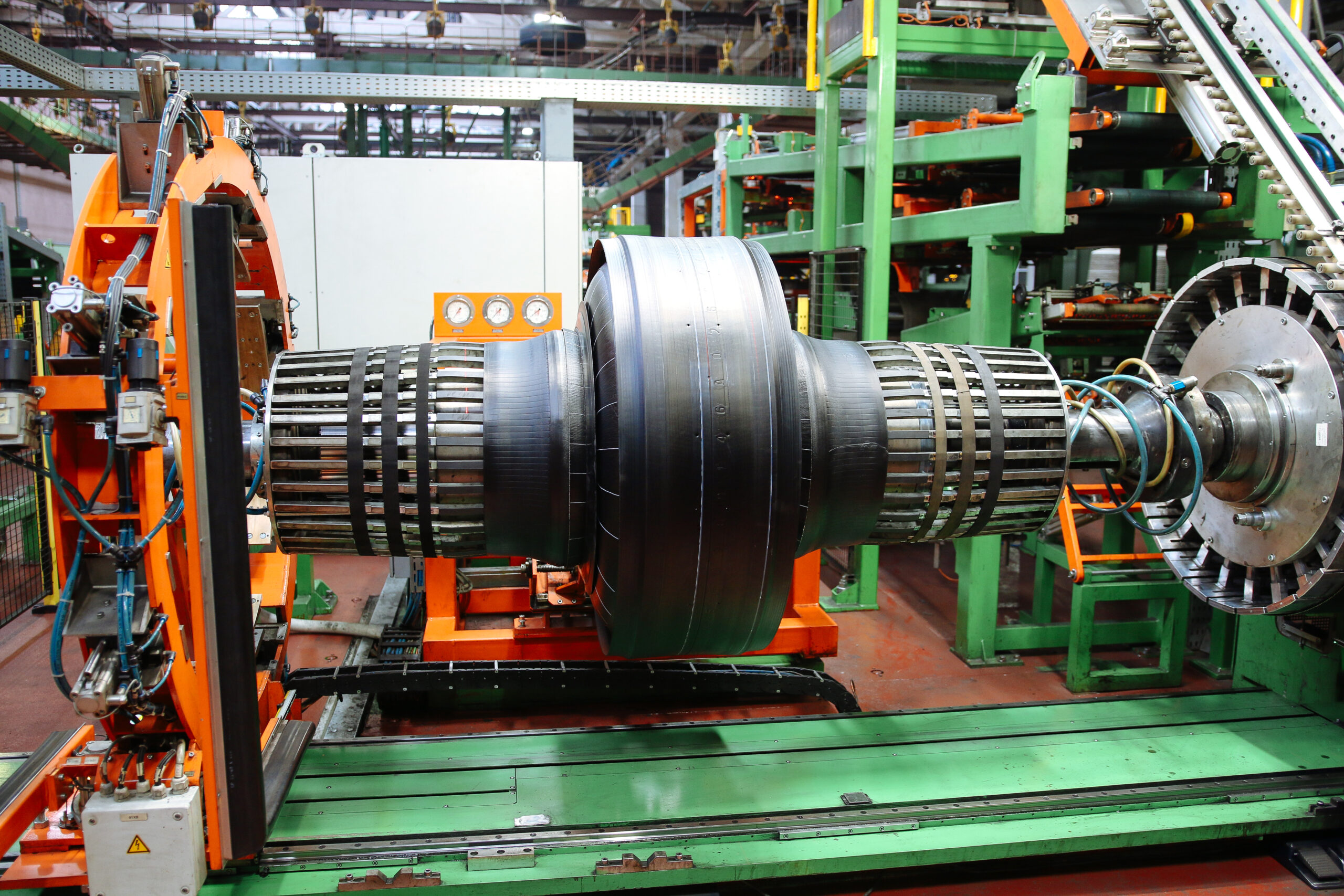

Positioning of rubber strips on drum during tyre production

Laser lines are used to mark the correct positioning of the rubber strips on the drum.. Three lasers are usually needed - one for the center lines and two for the outer lines. The outer lines can be adjusted depending on the width of the tyre. Lasers with green line... -

Determining exact width of the new tyre profile using lasers

To renew the profile, you have to determine the exact width of the new profile. This can be displayed with one, two or more laser lines so that the new profile fits perfectly.Home Case Studies Determining exact width of the new tyre profile using lasers Determining exact width of the new... -

Quality testing of tyres using thermal imaging

To see temperature distribution on tyre surface during different strains level thermal imaging with non contact infrared camera is used. Visual map of temperature distribution is providedHome Case Studies Quality testing of tyres using thermal imaging Quality testing of tyres using thermal imaging Online testing of tyres using thermographyVisual map... -

Full profile temperature measurement during plastics bottle cap sealing

Online thermal imager provides real time temp. streaming & imaging from all the defined areas. Several areas of interest are created. To check proper cap lamination, temperature must be higher a limit. Online tracking of temperature is possibleHome Case Studies Full profile temperature measurement during plastics bottle cap sealing Full... -

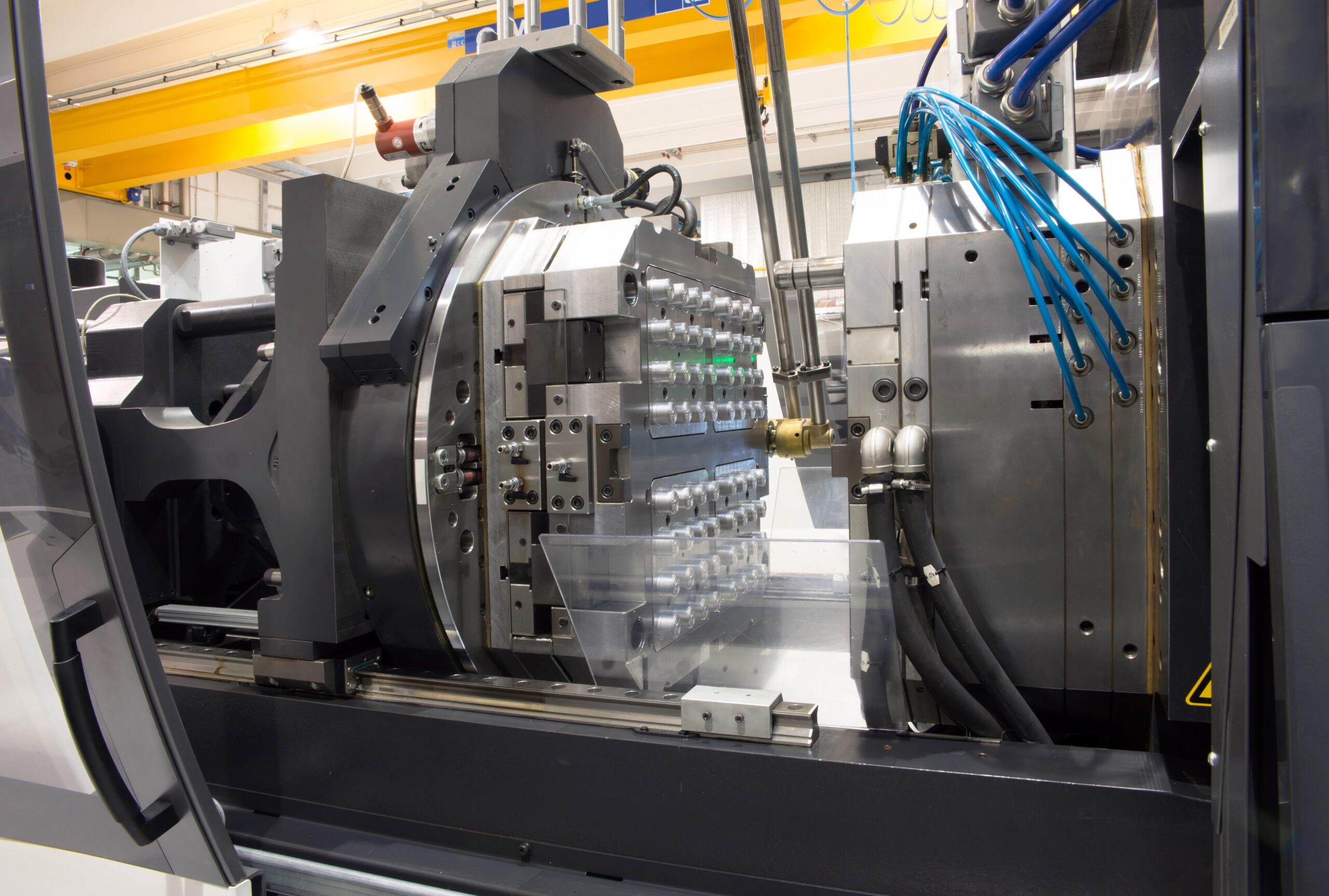

Accurate Non-Contact Temperature Measurement during injection molding, extrusion and blow molding

Home Case Studies Accurate Non-Contact Temperature Measurement during injection molding extrusion and blow molding Accurate Non-Contact Temperature Measurement during injection molding, extrusion and blow molding Accurate temperature measurement ensures homogenous wall thicknessMinimizes risk of expensive 'injection tool damage'Provides object actual temperature Challenge Overheating/ underheating results in undesired shrinkage and white-spots... -

Best Practice: Cable protection for aggressive environments

Home Case Studies Best Practice: Cable protection for aggressive environments Best Practice: Cable protection for aggressive environments Cable protection systems for aggressive environmentsAggressive fluidsMechanical loadsHigh ambient temperatures Application areas of sensor cable protection Emulsion: Overheating/ underheating results in undesired shrinkage and white-spots. Emulsion (eg Deflector roll, inside the mill) :...

Found 97 Results

Page 4 of 10

Page 4 of 10