For Secondary Steel Processing

Key Features

- Spectral spectral range: 0.85 – 1.1 μm

- Intuitive to operate

- Reduces process setup time and automate quality monitoring

- Broad temperature range and Continuous temperature monitoring

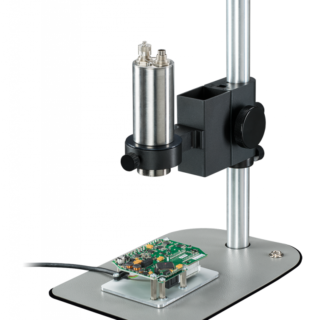

- Lens options for outstanding clarity at any distance

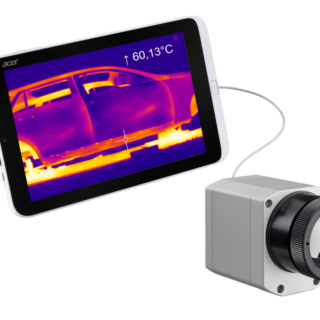

- High resolution thermal imager

- Customize and display zones overlayed on thermal image

- Real time large scale scanning with precision

- Prevents downtime and enhances worker safety

- Prevents costly failures

- Easily track temperature changes

Want to check if this is the right product for you?